Our pre-order system is pretty straight forward. First, you upload a design, gather orders, and then when your campaign has ended (assuming it gathered 5 pre-orders or more), we print and ship to your customers. While this pretty much sums it up, there’s a little bit more going on behind the scenes than is described above. With that in mind we’ve prepared a quick overview of the process:

Day 1

The plain stock that your campaign uses is sent directly from the garment brand warehouse and delivered to our production house the next working day, normally on pre 12 pm delivery. You’re often not the only one using a certain blank T-shirt, so we’re able to group shipments together to make the whole thing work more efficiently.

Day 2

Our production team receive, check and count the stock to ensure the correct sizes and colours have arrived and if there are any discrepancies, replacements are arranged to arrive the next day.

Day 3-4

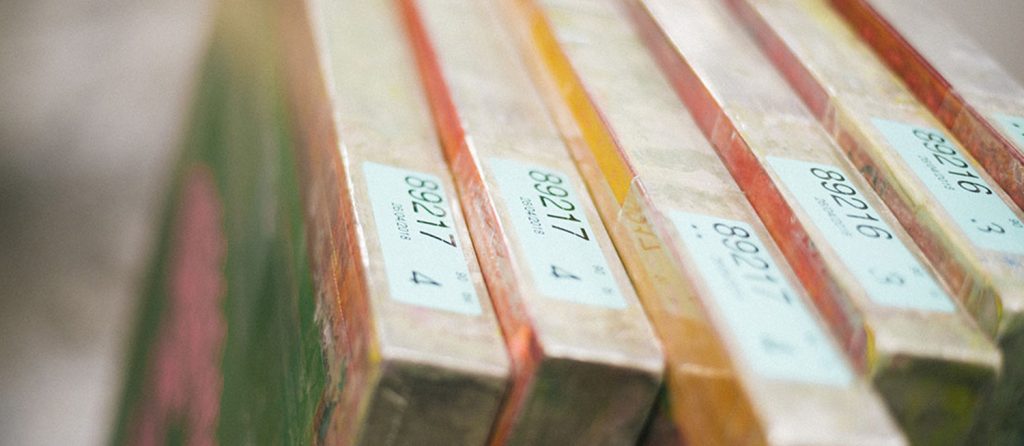

In the design department, we ensure your artwork is prepped into a print ready format and scaled to the correct size. If your campaign is to be screen printed, then screens are made using your artwork.

Remember: We only print using vectorised, hi-resolution artwork so be sure to submit this to our team before the end of any successful campaign to ensure the best print quality possible.

Day 5-6

The campaign job is booked into the daily production schedule, the inks are mixed and the machine, depending on your print method, is set up. A sample is produced first and, once it’s been carefully checked and approved, all items from the campaign are printed in one batch and finally run through a tunnel dryer so the ink can cure.

Once they have passed through the dryer they move onto the fulfilment department where they are carefully folded, bagged and packed with our 100% recyclable mailing bags.

Finally, postage labels are applied, and the packages are collected by courier at the end of the day and taken by van to the local delivery depot. From here they start their journey to buyers around the world.

Remember: Shipping times will vary depending on your location, for our usual shipping times and rates, check here.

Want to know more about our primary print methods? Head to our guides on screen and DTG printing here.